This week, we continued researching and exploring the best direction for our project to take. On Monday, our clients dropped off a box of a few hundred 3D-printed track pieces that could be assembled together into a modular pump track. We took some time to get familiar with the different types of pieces and create some tracks of our own with different elements.

We had some major design questions that we needed to make sure to answer before we made any decisions about the project before quarters. We discussed more with our clients about the structure of the pump track design competition they would be running in the spring, so that we could make decisions with the proper context in mind. We learned that there would be small groups of 2-3 students working together to create their designs, and that the goal was to have a community showcase of their designs, meaning that our project needs to provide a good experience for both the players and spectators.

We also wanted to learn more about how to determine whether a pump track was actually good or not. Since the students who will be designing these tracks are not professional engineers, it mostly comes down to how the track feels to ride on, and it’s important that the kids have agency and creative freedom in making the track look how they want to. We want our project to instill in the students an enjoyment of the process of designing the track, as well as confidence in themselves, so they can see a future career for themselves in STEM fields and believe themselves to be capable of pursuing the further education required to master these skills.

Some team members attended the CMU Libraries Research Review session and Dave Culyba’s Transformational Design Workshop this week, so we could have more resources available to deepen our understanding, and we could hear more perspectives on how this project could accomplish its educational goals.

After exploring all of the possible platforms we could use for our project, we narrowed it down in a discussion with our clients. Our project needs to support both building and riding on tracks, and we thought that PC was the platform that made the most sense. Keyboard and mouse inputs were used often for building programs that we were referencing, and there were a lot of existing conventions. For the track riding, we could use XBox controllers that could be connected easily to a computer. Though our clients were initially very excited about using VR headsets, they would have been limited in the ease of collaboration and spectating, and they would be more difficult to run even for an individual player. By using PC as our platform, we could also more easily have one combined app with both components, rather than having to develop cross-platform capabilities from the start.

On top of these regular controller, we also pitched building a custom controller that players could choose to use for the riding portion instead of the XBox controllers. This custom controller will be based on BMX bicycle handlebars and would use load cells (weight sensors) to detect pushing and pulling, in order to emulate the sensation of actual pumping and create a more immersive experience. Our clients are very excited about the idea, and we think it would work especially well in the community showcase environment, where more people beyond just the Ruach students can try playing with it. To prototype the controller, we are planning to use Phidget sensors, which are fairly simple to plug into a PC and use in the Unity engine, and then 3D printing the structure that will need to hold the sensors to make the controller work.

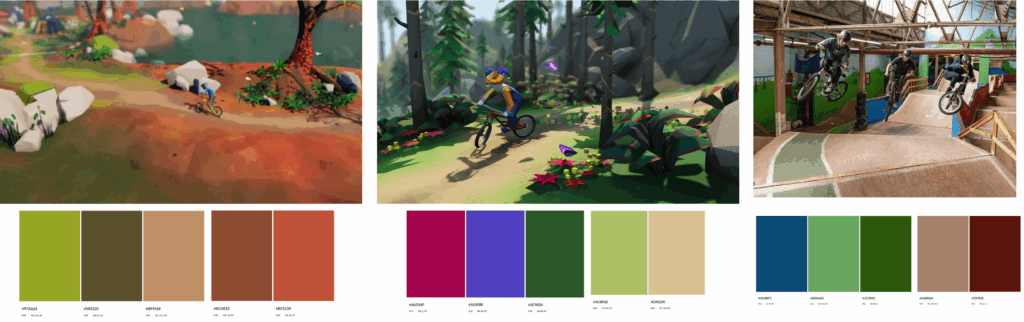

We began to also collect inspiration for the art style of the project, looking at low poly games like Lonely Mountains Snow Rider, games about riding bikes, and BMX tracks. Looking at their color palettes, we noticed a common pattern of earthy and natural colors.

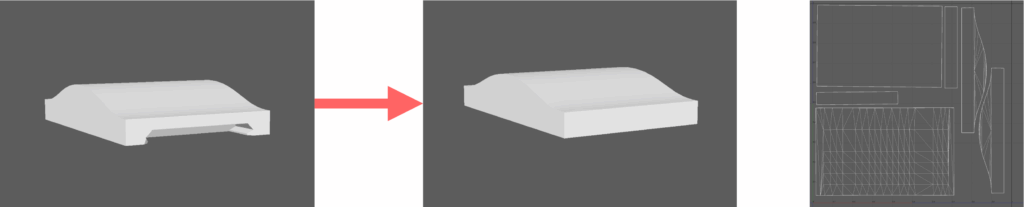

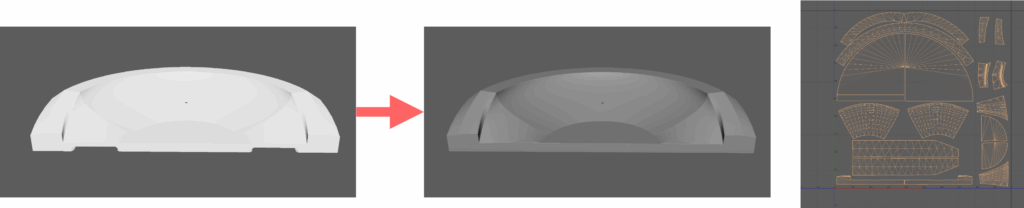

Since we knew that our experience should use the same track pieces as what our clients had 3D printed—with the possibility of creating more—we got access to the files that were printed and edited them to remove the slot for the connector piece needed for the physical pieces. Then we made UV maps in Maya for all nine provided track pieces.

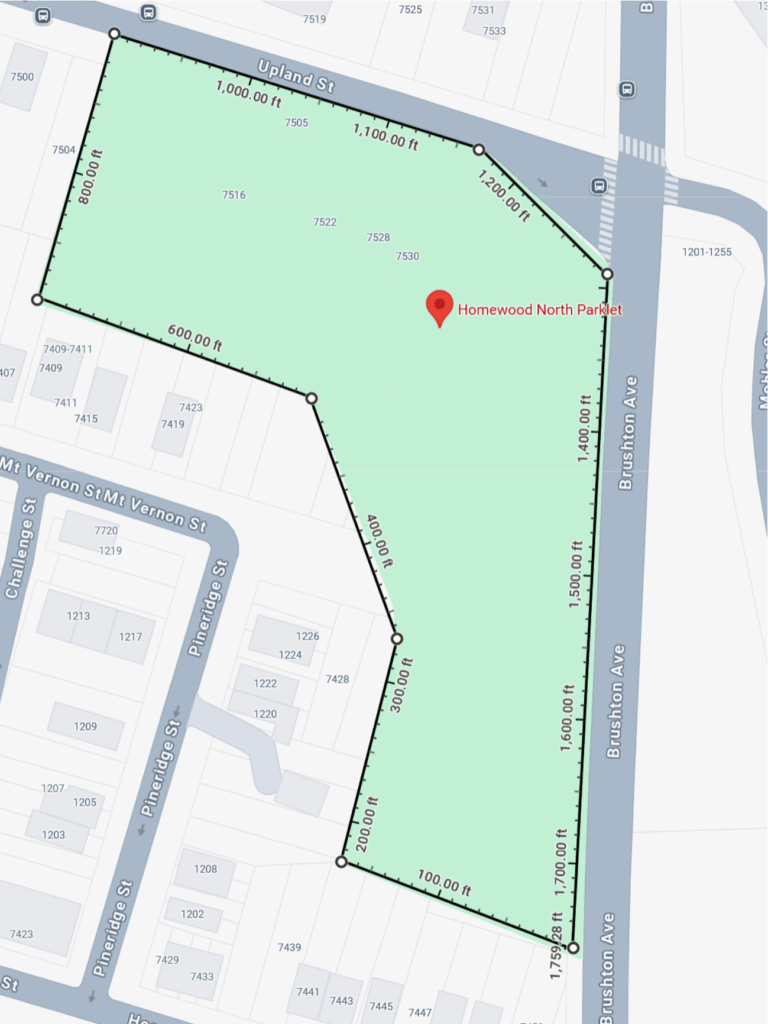

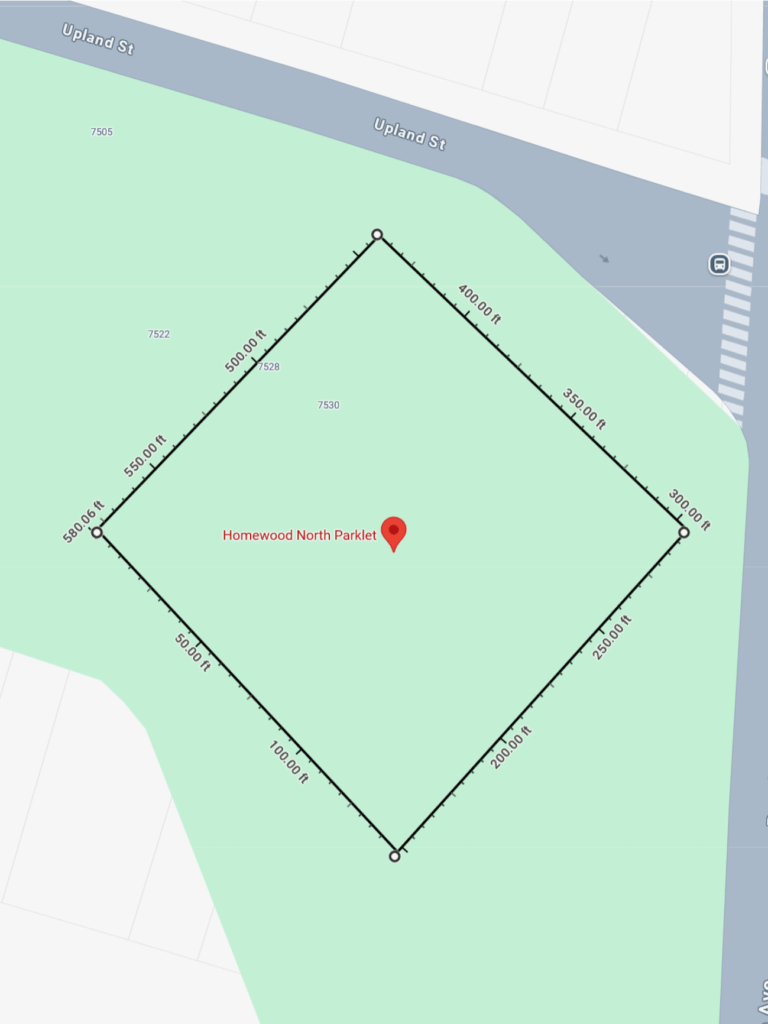

We also got information about the current planned location for the new park and pump track, which would be Homewood North Parklet. There is about a half acre square in the center that would be allocated to the pump track, which we can create to scale in our program.

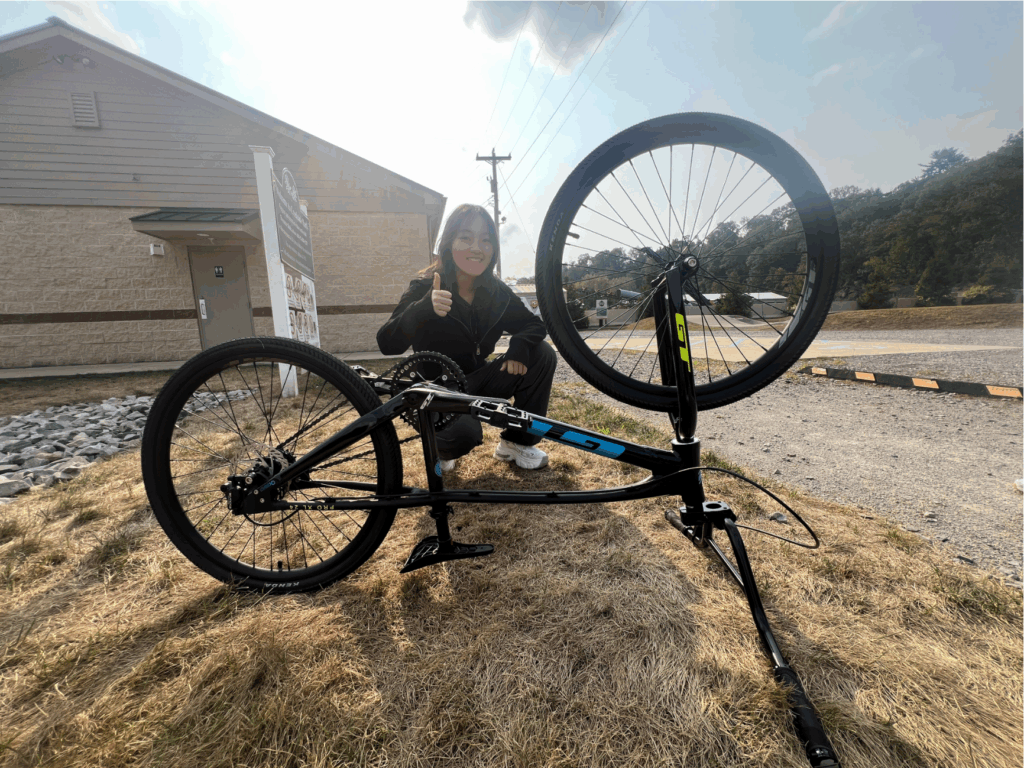

We wrapped up this week by taking a short trip with our clients to a local pump track in Oakmont Park, where we got to try out riding on a pump track for the first time! It’s more difficult than the skilled riders make it look, and there are many factors to think about all at once, from timing to speed to your body position. Getting to experience this for ourselves was very informative and fun, and it will give us a much better sense of how realistic our project feels down the line.