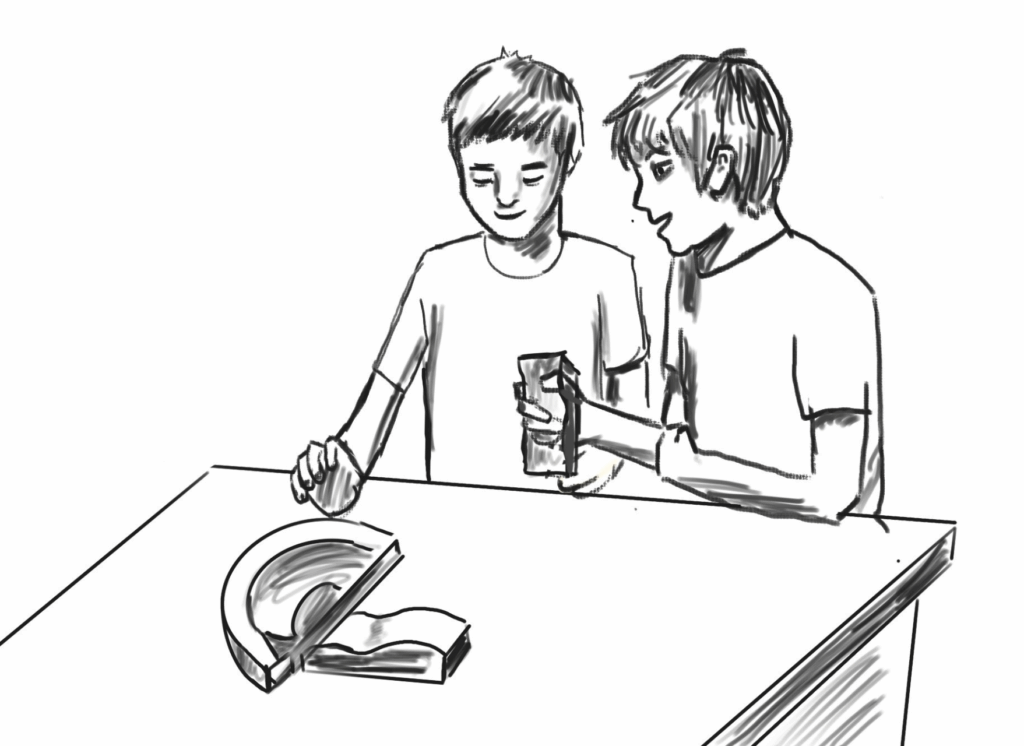

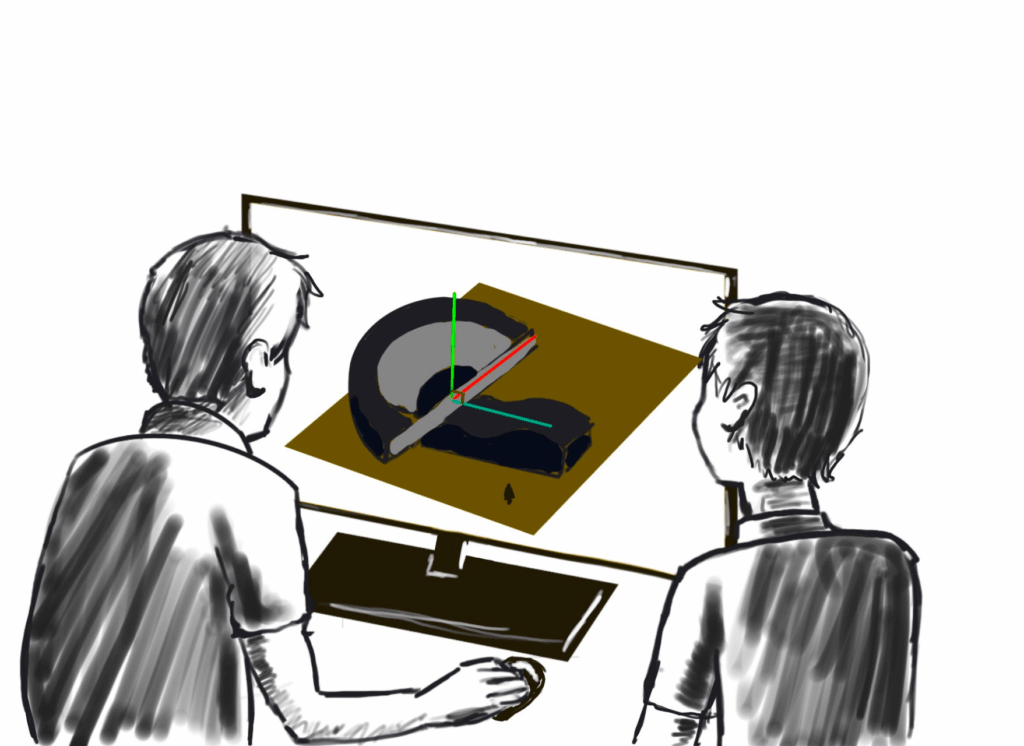

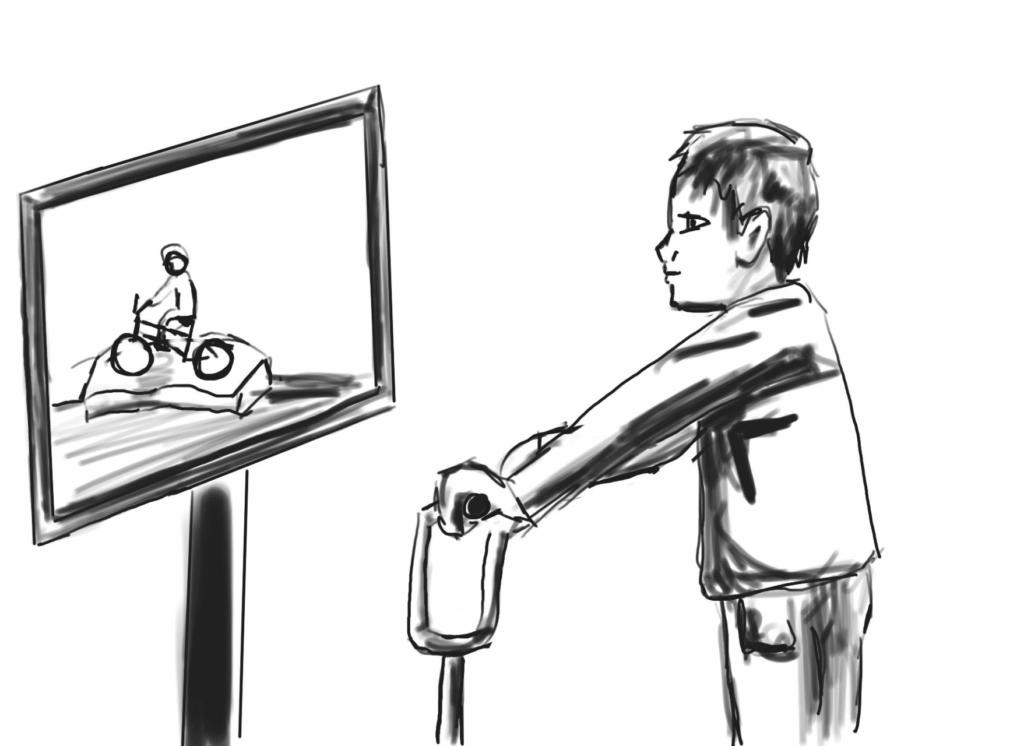

For Quarters, we presented a storyboard of our experience and received valuable feedback from faculty. In our client’s pump track design competition next Spring, groups of students will first get to prototype their designs using the 3D-printed track pieces. Then, our program will allow them to modify these tracks with additional flexibility compared to the physical pieces, as well as design the broader community space. They will be able to test out their tracks with our riding simulator, for which we are designing a custom controller, and eventually a winning design will b e chosen by the community and built into a real park.

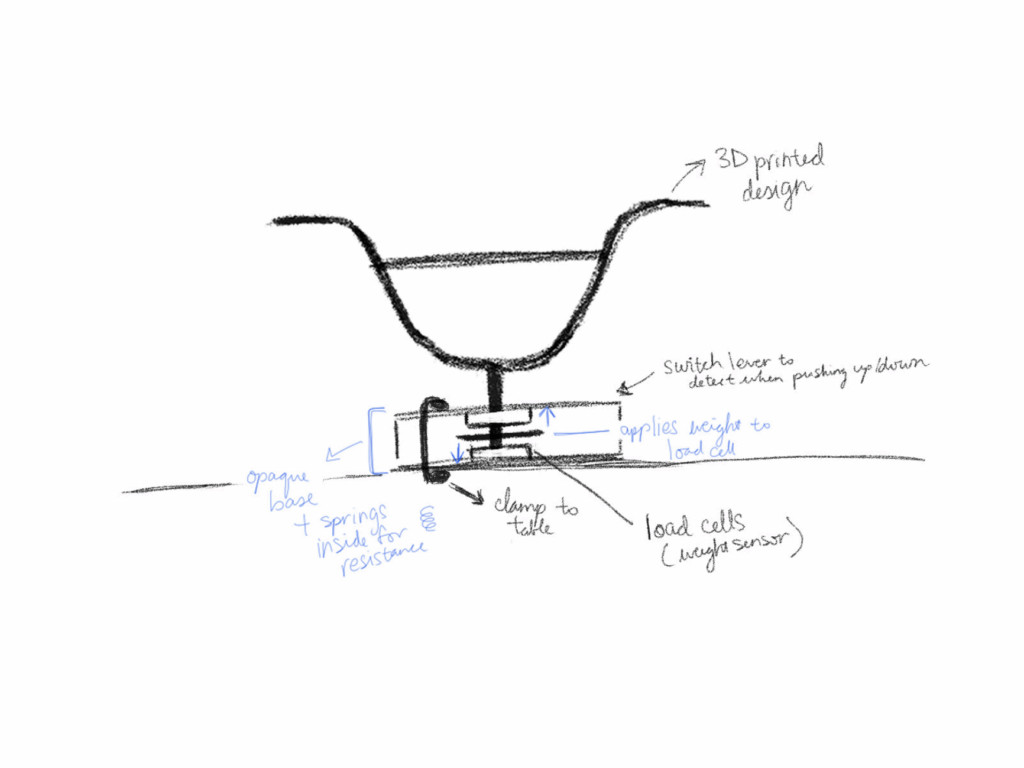

For the custom controller, we created this initial design, where we would have two load cells mounted to a box, one on the top and one on the bottom, using a 3D-printed structure of a shaft going through a plate to trigger the sensors when a user either pushed down or pulled up. At the top, we would print a structure resembling bike handlebars. The box would be clamped down to the table to support pulling the handlebars up, and springs around the shaft above and below the extruding plate would help provide tension to improve the feel of the pumping motion.

The faculty immediately gave us feedback that trying to 3D print the entire structure was not a good idea, and that we should just buy a real set of handlebars. Part of the reason we gravitated towards 3D printing was that it would be accessible to both us at the ETC and our clients, who had 3D printed the modular track pieces. They would also like for our project to be easily shareable with other educational programs, so it would be helpful to make the controller easy to assemble. We agree, however, that 3D printing a structure that is so large would not work, and in this case, just buying a set of handlebars is even more accessible to the bicycle club.

Other feedback that we received was to define our constraints very early and clearly define the parameters that we need to use to judge a pump track, such as what it means for it to be based on aesthetics. We also got some suggestions for works we could look at for inspiration, notably Roller Coaster Tycoon.

We started getting into actually developing the product, based on what we knew for sure that we would need to have. On the art side, we needed to texture the track pieces to resemble asphalt, which is what the real-life track will be made from. The initial texture was made from layering 2D rock patterns created in Photoshop, using a Photoshop Pattern script to randomize their sizes and placements. We got feedback that this texture looks more like water droplets than rocks, so we will continue iterating on this.

We started doing some early tests of the bike package’s control schemes and adding a pumping motion. We found that we more or less have to fake the motion by adding artificial forces because just shifting the character’s center of mass doesn’t have much of an impact. We apply force to the character based on the slope of the track and their current speed. For some proof-of-concept controls, we mapped pumping up and down to the Q and E buttons. This initial version is working to some degree, but we need to still figure out the appropriate values for the speeds and forces. With the existing physics system, the bike moving too quickly often causes it to lift off the track, where the movement of the bike cannot be controlled. We will continue building upon this system and fine-tuning it to feel as smooth and realistic (without actually being realistic) as we can get it.