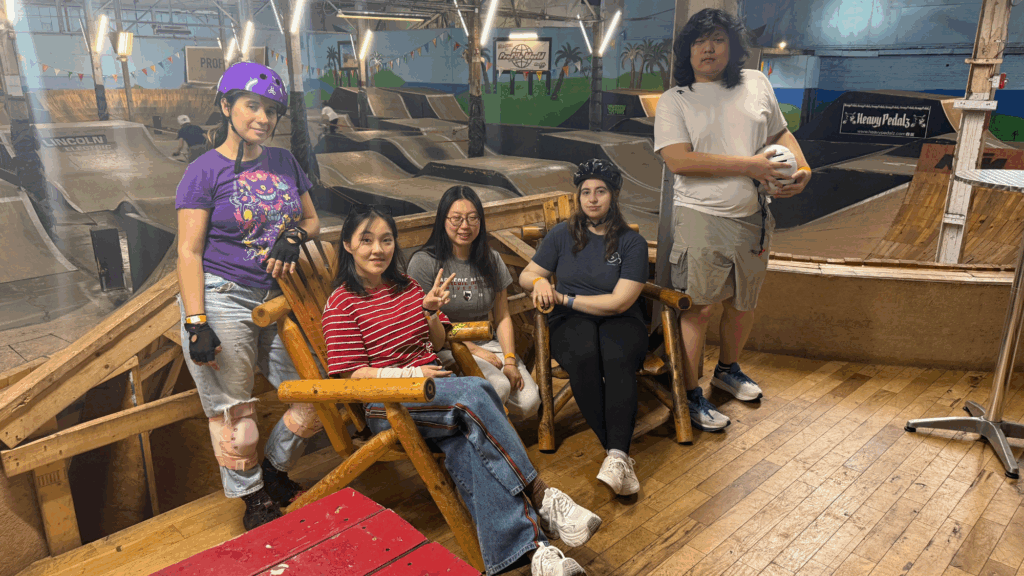

This past Sunday, September 14th, the team traveled with our clients—including the students who will be participating in the pump track design workshops and competition—to Ray’s Indoor Mountain Bike Park in Cleveland, Ohio. We rented BMX and mountain bikes and practiced riding on the pump tracks, learning about the elements that make some tracks more difficult vs. beginner-friendly.

We also got to directly talk with our target audience and learn about their interests and background in both biking and playing games. They all said that pumping is the most important technique in riding on these tracks, so getting that mechanic to feel accurate in our simulation is crucial. The kids have played a lot of sports games, and they are used to games foster creativity and allow them the freedom of building, such as Roblox, Fortnite, and Minecraft. They are interested in progression, increasing difficulty over time and gaining skills and mastery.

Going into this week, we came up with priorities the next milestones of the project. By Week 6, we want to have a playable prototype that we can playtest on main campus and with our clients. That prototype should be able to support a version of track building and riding, and we should have a version of the custom controller that does something. By halves, we should also have started adding some of the aesthetic components like the additional amenities that can be added around the track. To the point of aesthetics, we need to balance the wish for customization features (for the characters, bikes, etc.) with our prioritization of the pump track design competition that the project is servicing. A good compromise for us to implement very simple customization, like swapping out the colors of a texture on lines painted on a track piece, for example.

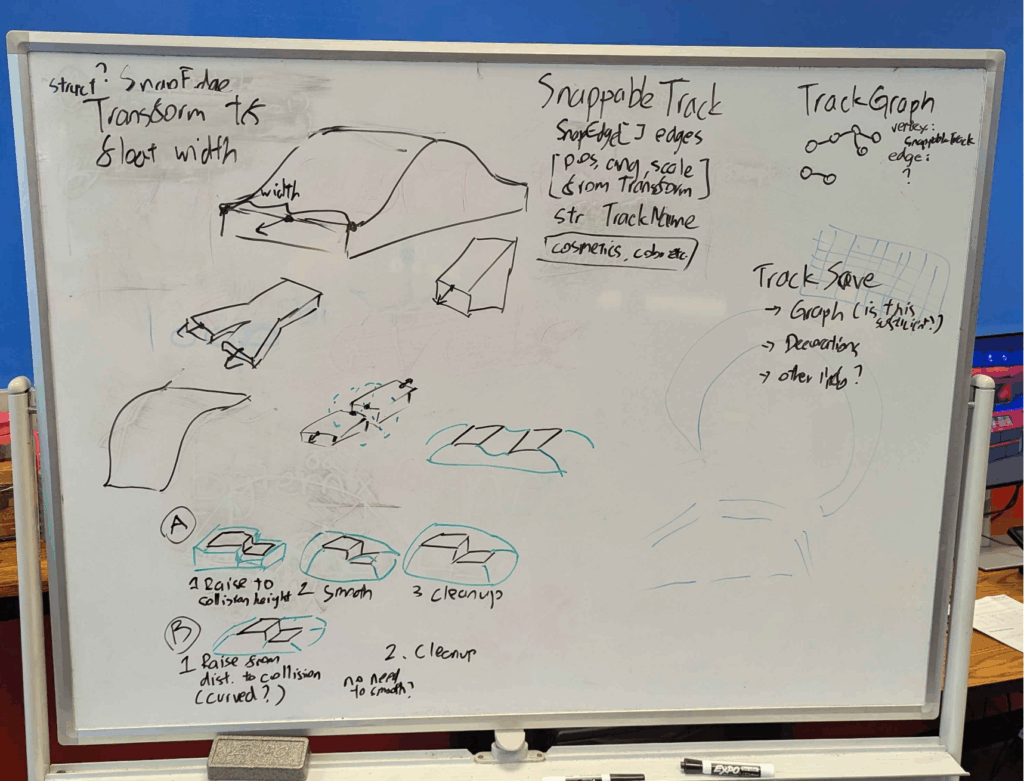

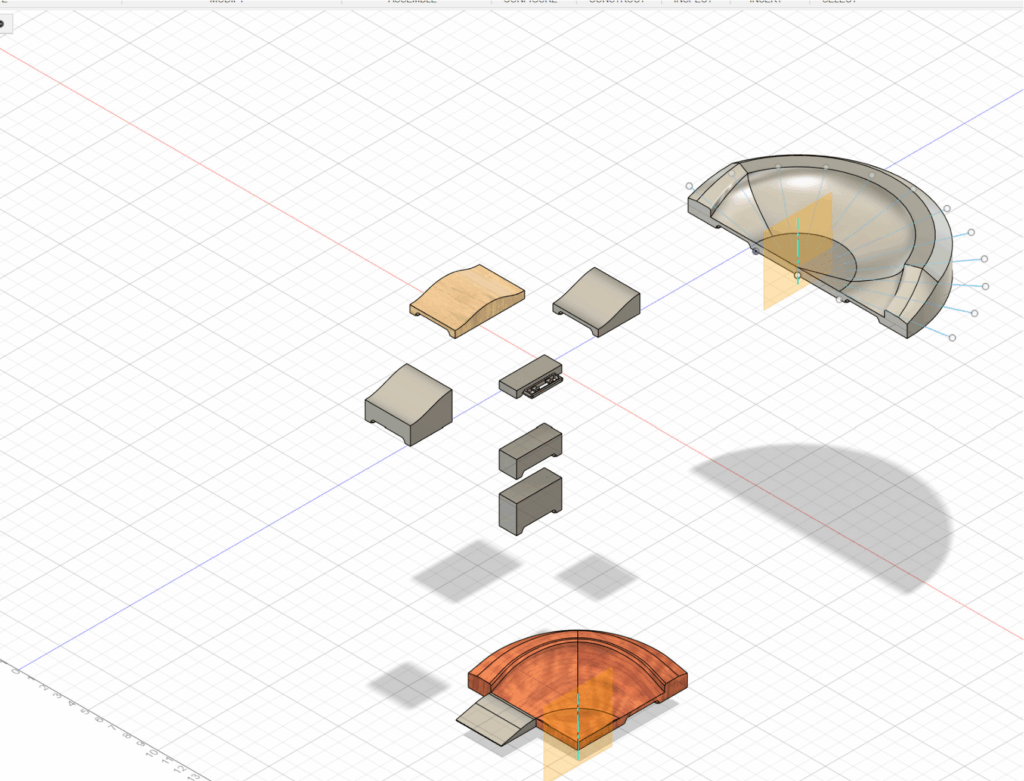

On the tech side, we began working on the system for track building, creating the basic code layout for the different types of track pieces and data needed to be able to save and load pump track design files.

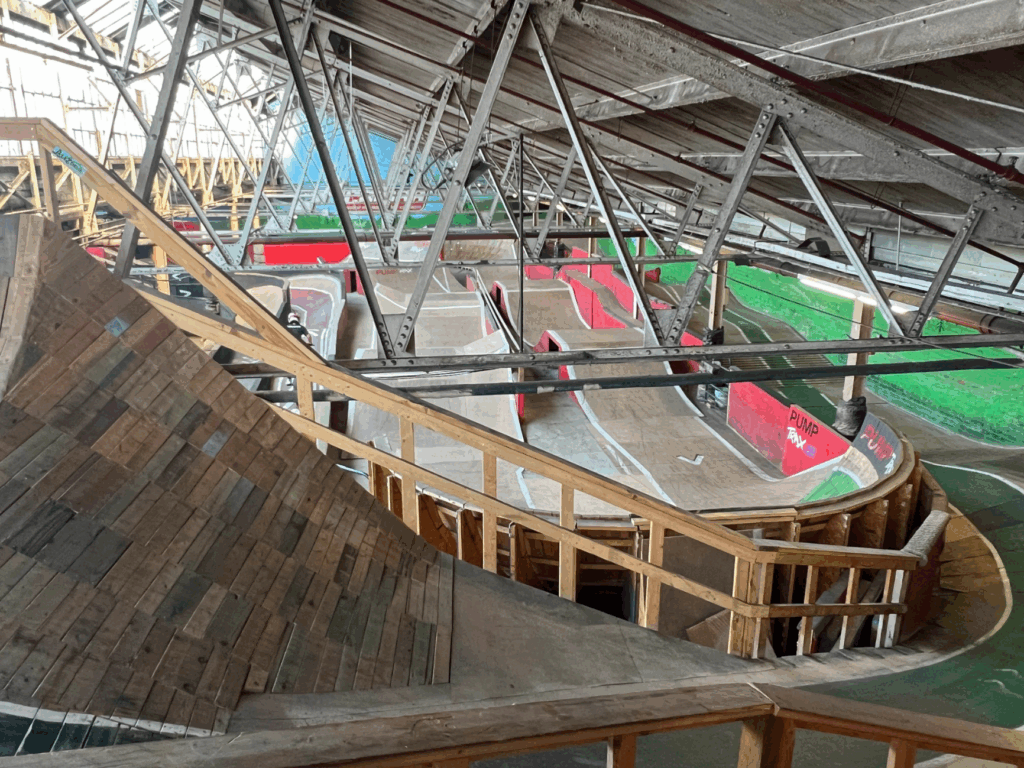

We also theorized about some options for how to shape terrain around each track piece to make the pieces look like they have been dug into the ground, rather than sitting flat on top of the ground, in order to better match how our clients will be building the real-life pump track. While some companies do provide modular pump track pieces that they will assemble fully above ground, like some of the tracks that we saw at Ray’s, the final pump track that our clients will build at the park will be more similar to what we saw in Oakmont park, where the track is carved out of the dirt, with asphalt laid on top.

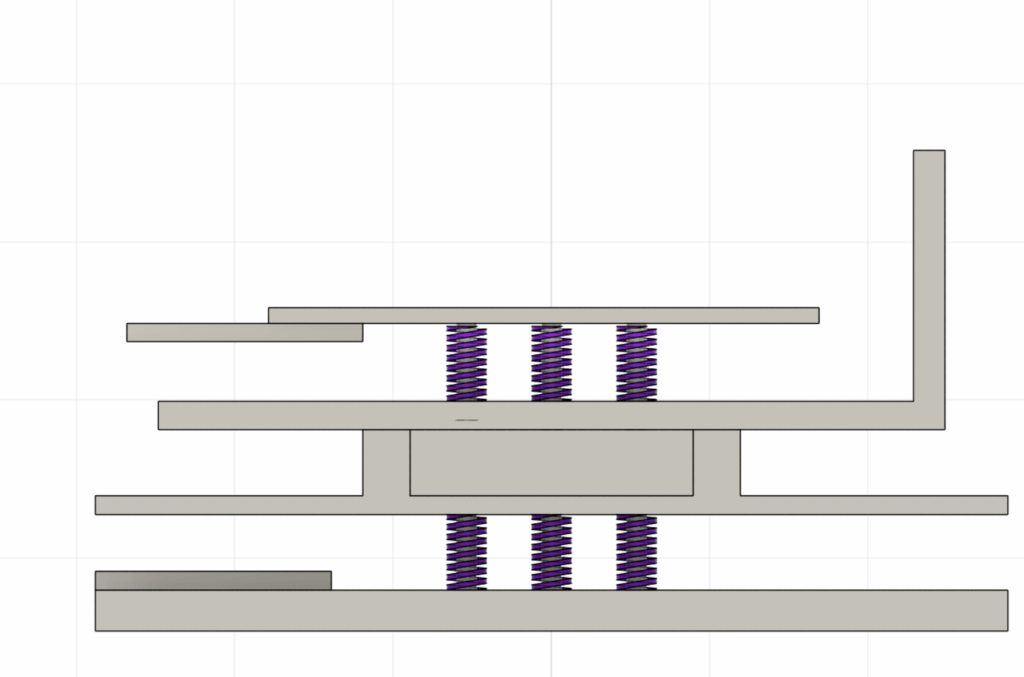

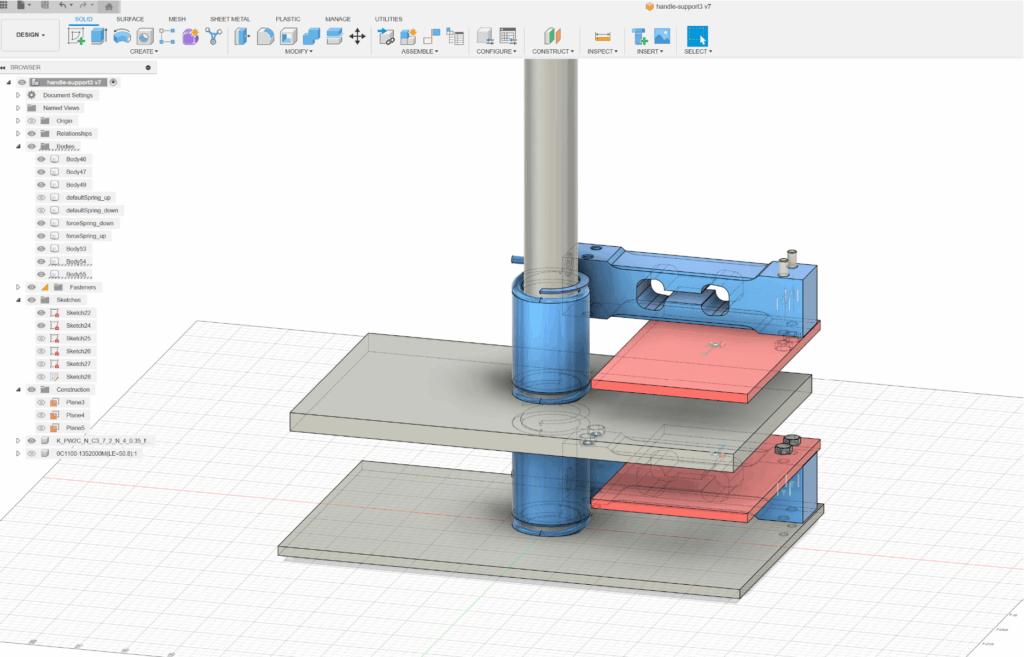

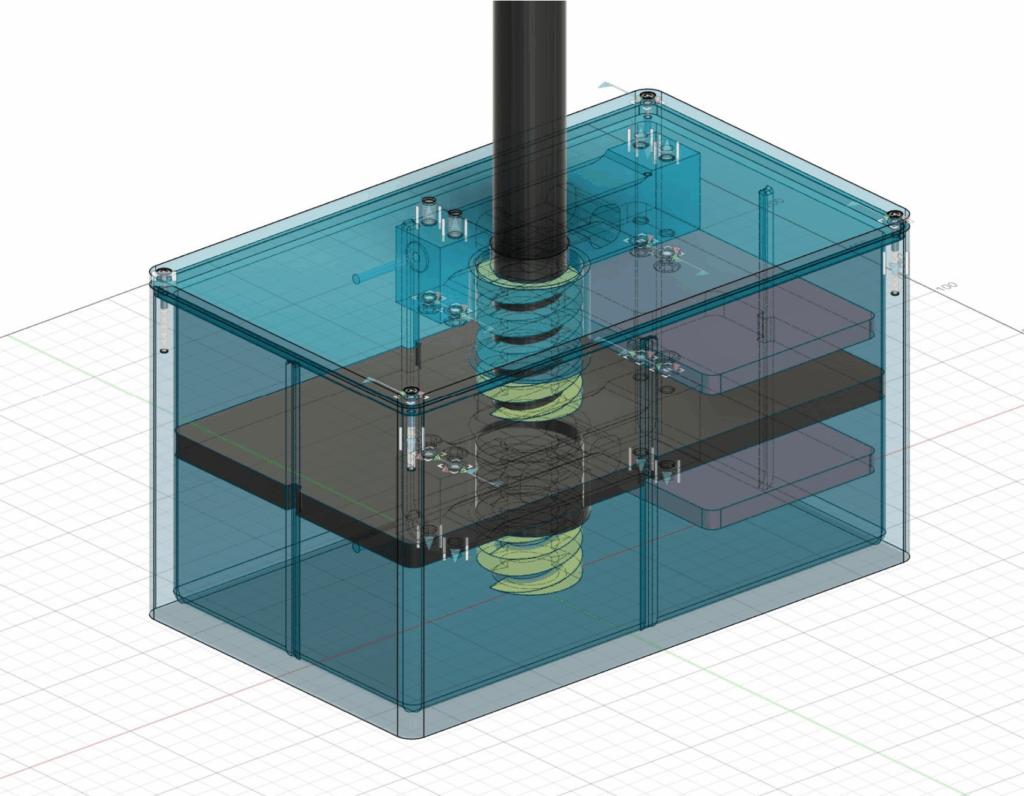

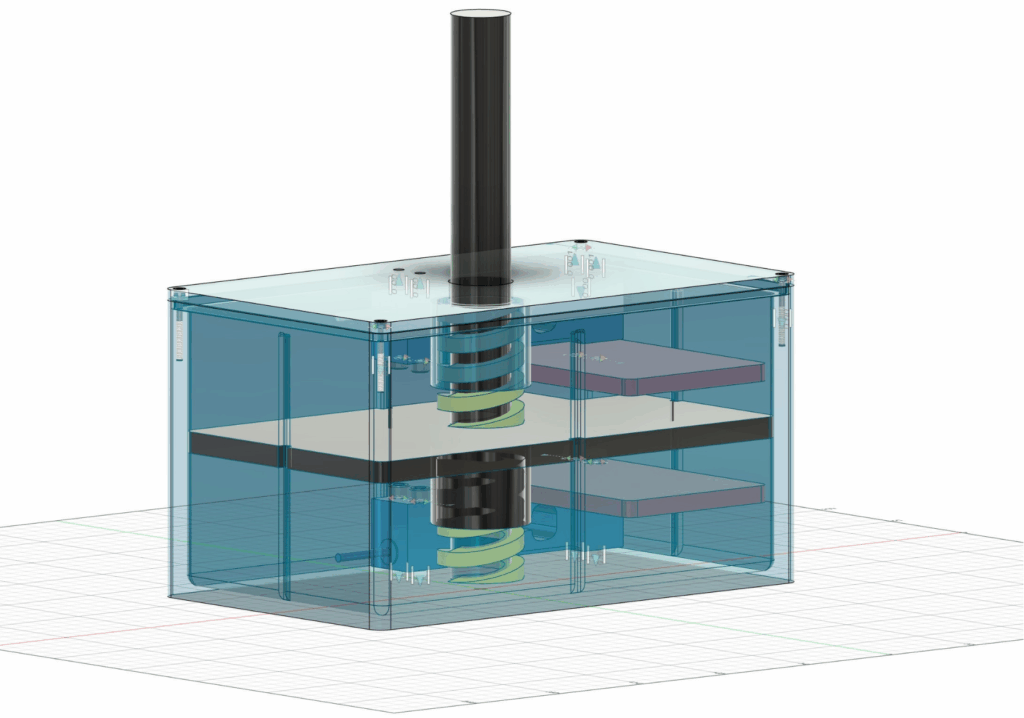

With the initial design for our controller adapted after the feedback that we received from Quarters last week, we started designing the internal structure that we will be 3D printing. The first iteration had the shaft connected to a plate with three rods with springs supporting the pumping movement up and down.

We pivoted shortly after to just one shaft directly under the handlebars and only one pair of springs, so that we could better support the rotation of the handlebars for steering.

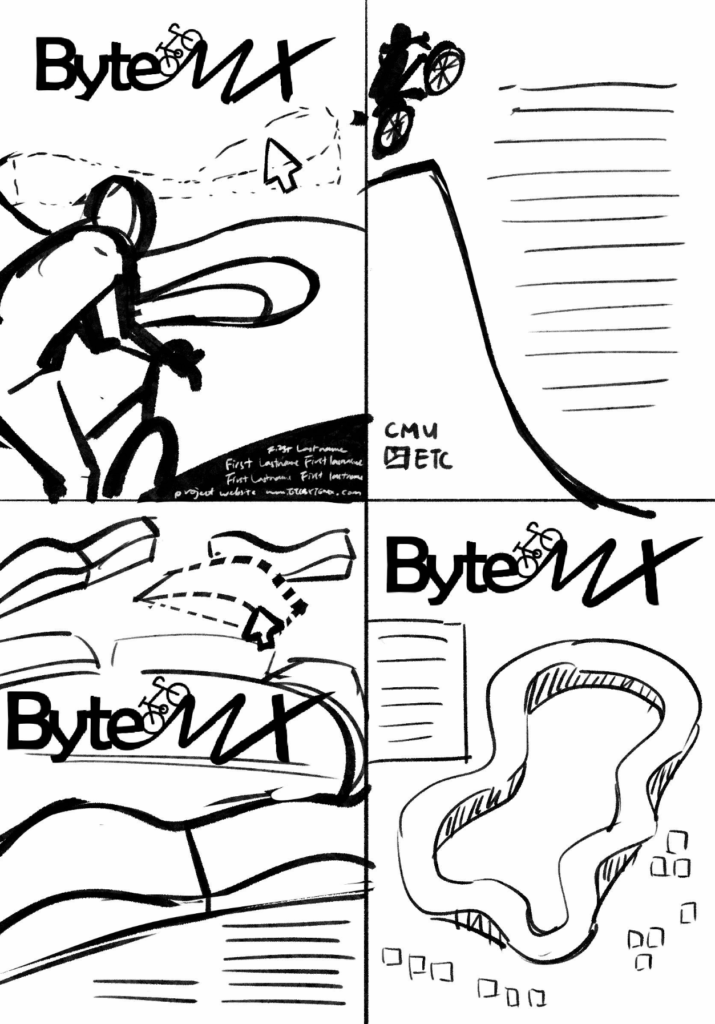

At this point in the semester, we are also working on our project’s identity and design production. We started setting up our website, working on our team’s logo, and drawing thumbnails for our poster and half-sheets. By next week, all of this media will be finalized.