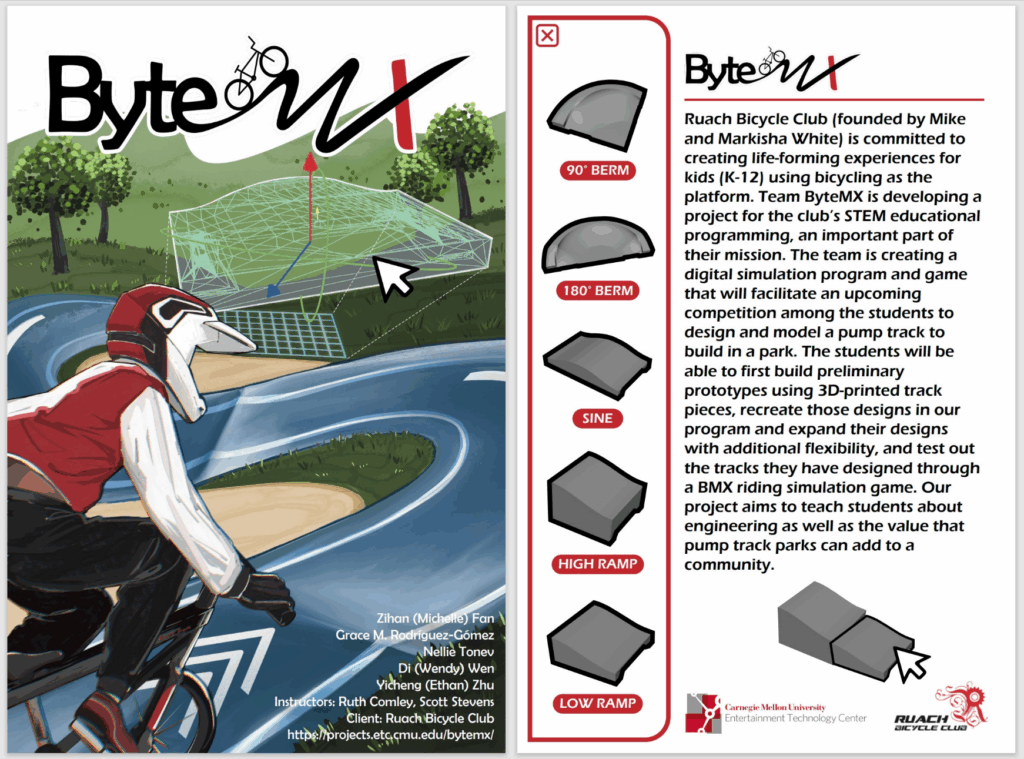

Our team’s identity, logo, and half-sheet are finalized! The image on the front of our half-sheet and poster reflect the essence of our project, with a BMX bike rider character riding on a pump track that is actively being built digitally with a mouse dragging in a sine piece in the background. The back side of the half-sheet has a summary of our project goals, along with a list of the track pieces, so that anyone who picks up this sheet can quickly learn something new if they are not familiar with pump tracks.

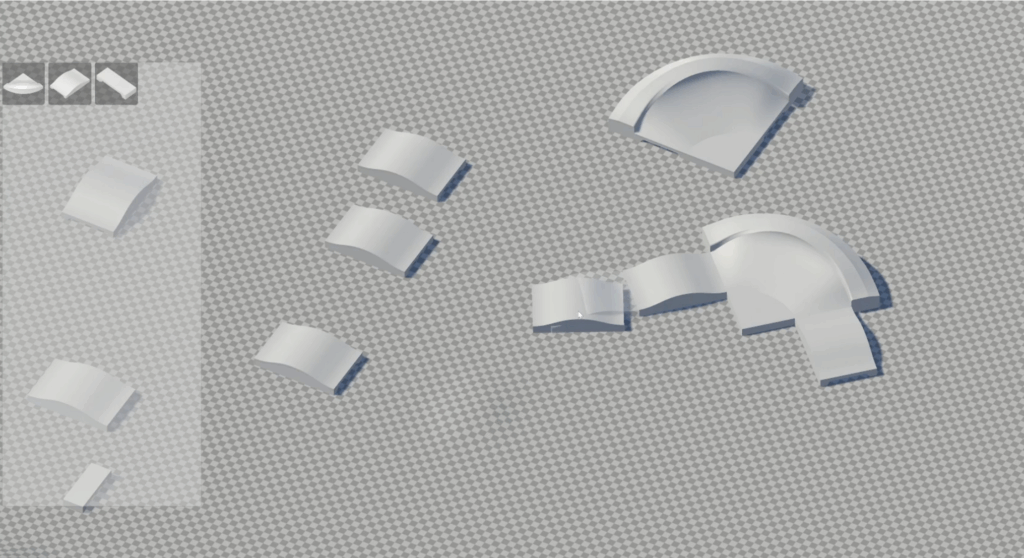

We continued building the core systems on the tech side of the project, this time focusing on the drag-and-drop track building system. We have a list of snappable track piece object that store data about their edges that can connect to other pieces, including the position and rotation of the center, as well as the width of the edge. We implemented a system of dragging from an icon in the UI to the 3D model in the scene, and the pieces can snap together with each other in the same way that the physical 3D printed pump track pieces can. We also added necessary collision checks for determining whether a particular placement of a tile was valid, as well as a translucent preview of where a piece will end up before snapping, which provides confirmation that users can connect the pieces as expected.

We also had a meeting with Mike Potoczny, a subject matter expert and pump track designer who works with the Ruach Bicycle Club. He answered a lot of questions and clarified a lot for us in terms of how to design a pump track and what makes a design effective. We learned that pump tracks are often designed to be accessible to riders of all skill levels, with some paths that will be more consistent and beginner-friendly, while others that have less consistent spacing, making it more difficult. Beginner riders will ride over every element of a track, while more advanced riders can jump over and skip some elements or even jump between different pathways.

Some risks when designing a pump track are that the spacing is too tight for a bike to comfortable fit within, or that it’s too flat. The track can become very dangerous if the spacing between elements is too close together, or if there are areas that cause inexperienced riders to gain too much speed without control, such as a roll in that’s too steep.

As a designer, he currently does his work in SketchUp and other 3D design software, but in general, he says that designs don’t need to be too precise in the engineering. He thinks that having a way to prototype modular track designs through the tabletop pieces and then with our digital program will make the process much easier to understand and achieve for the Ruach students, who are in middle school and high school.

For next week, our upcoming milestones are to create a playable prototype for playtest night on main campus on Tuesday evening, as well as for a playtesting session with our clients and the students at the Ruach Bicycle Club next Friday after school.