Client & Partner Alignment

Early in the week, we scheduled our Zellerfeld meeting for Wednesday, September 24, with a pre-alignment session the day before to make sure our asks for both Zellerfeld and Ansys were crystal clear. In parallel, we kept building toward our end-of-week meeting with Ansys, ensuring our design and prototyping work tied directly into their expectations.

From our previous session with Chris and Ethan from Ansys we dove deeper into their simulation workflow. One of Ethan’s most useful insights was how simulation iterations multiply:

- Every shoe design × every material × every test = one iteration.

- Even two sneakers (e.g., high top and low top), paired with a few materials (zNylon, zLycra) and tests (split tear, abrasion), already result in dozens of simulations.

This highlighted the need to limit variations to keep simulations feasible. We even saw a stress test demo, which helped us visualize possibilities. Ansys suggested they might be able to mimic Zellerfeld’s lattices in their system; though material details from Zellerfeld will be crucial.

When discussing outputs, we explored:

- Numeric values (easy to share, harder to interpret)

- Simulation mp4s (great visuals, but heavy and outside our art style)

- GLBs (3D models only)

We may need to animate our own particle systems based on Ansys’s data to balance technical accuracy with engaging aesthetics.

Gameplay Loop Development

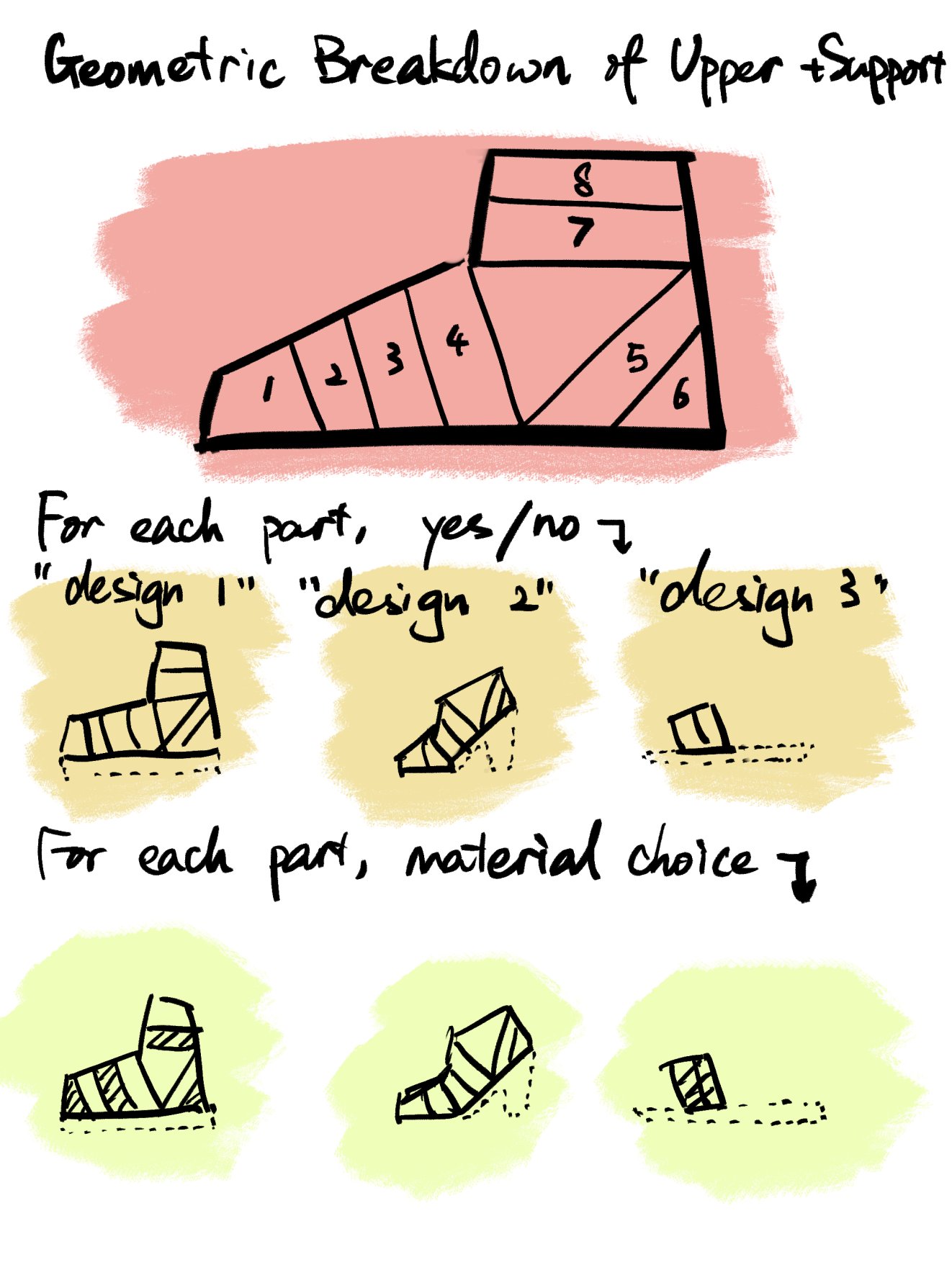

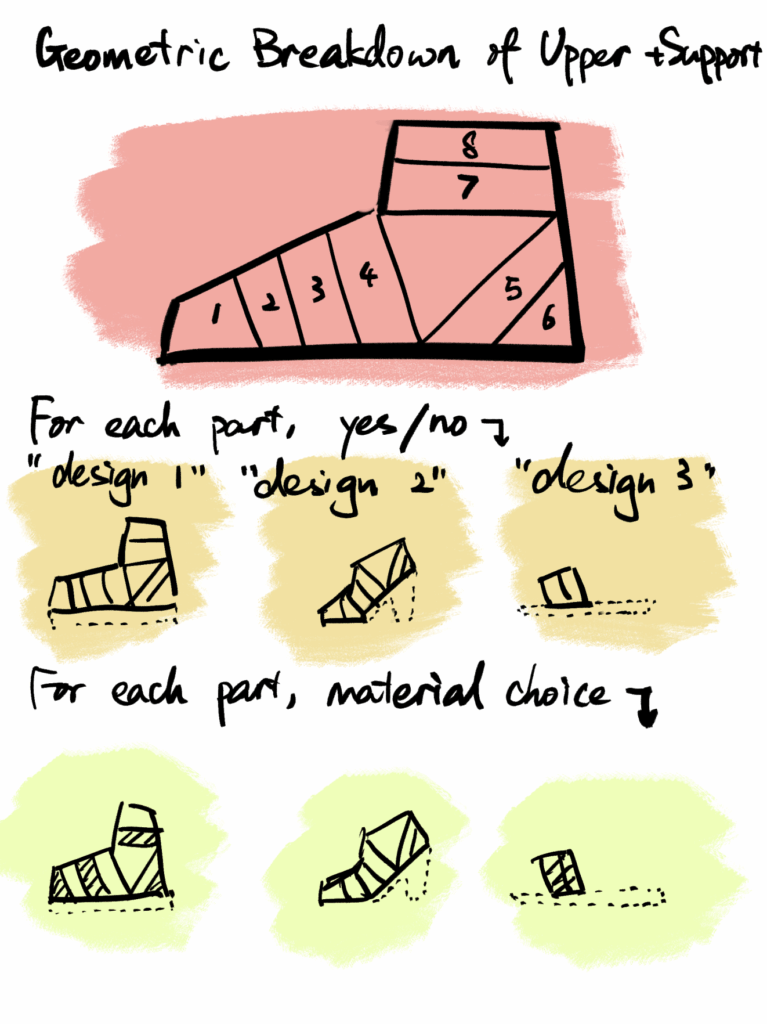

We refined the core mechanic of our transformational shoe testing game: players start with a broken shoe and diagnose its issues by running simulated tests on different components.

- Shoe Types: high-top sneakers, low-top sneakers, rainboots, sandals, and high heels—each with unique material and structural challenges.

- Component Breakdown: upper, midsole, and outsole defined for each shoe type, with materials including Nylon, Lycra, Cambrelle, EVA, synthetic leathers, and various polymers.

- Simulated Tests: part-level tests (split tear, resilience rebound, din abrasion, compression set, slip resistance, tensile strength) and whole-shoe tests (e.g., tensile strength, slip resistance) mapped to components.

Problem Mapping

We also finalized a preliminary list of potential shoe problems for players to diagnose:

- Pronation and supination

- Lever inefficiencies

- Toe box and heel scraping

This mapping grounds the gameplay in real-world engineering challenges while keeping it engaging and educational.

Integration of 3D Printing Insights

Our meeting with Tim from Zellerfeld gave us key insights into 3D-printed shoes that shaped gameplay design:

- Rigidity Levels: shoes generally use three stiffness levels, represented in-game as toggleable material property sets.

- Single Print Structure: no secondary assembly, reinforcing our approach of treating shoes as unified components with adjustable properties.

- Material Properties > Exact Materials: prioritizing property sets over direct material replication aligns with our simulation-based design.

- Biomechanical Considerations: designers address foot problems through shoe structure and stiffness, a concept we can weave directly into our diagnostic gameplay.

Iteration & Material Testing

With these insights, players will experiment with materials and reinforcements to solve problems. For example:

- Reinforcing the toe box to prevent splitting

- Adjusting midsole padding for compression/rebound

- Selecting outsoles to improve slip resistance

- Toggling stiffness levels to see how rigidity impacts performance

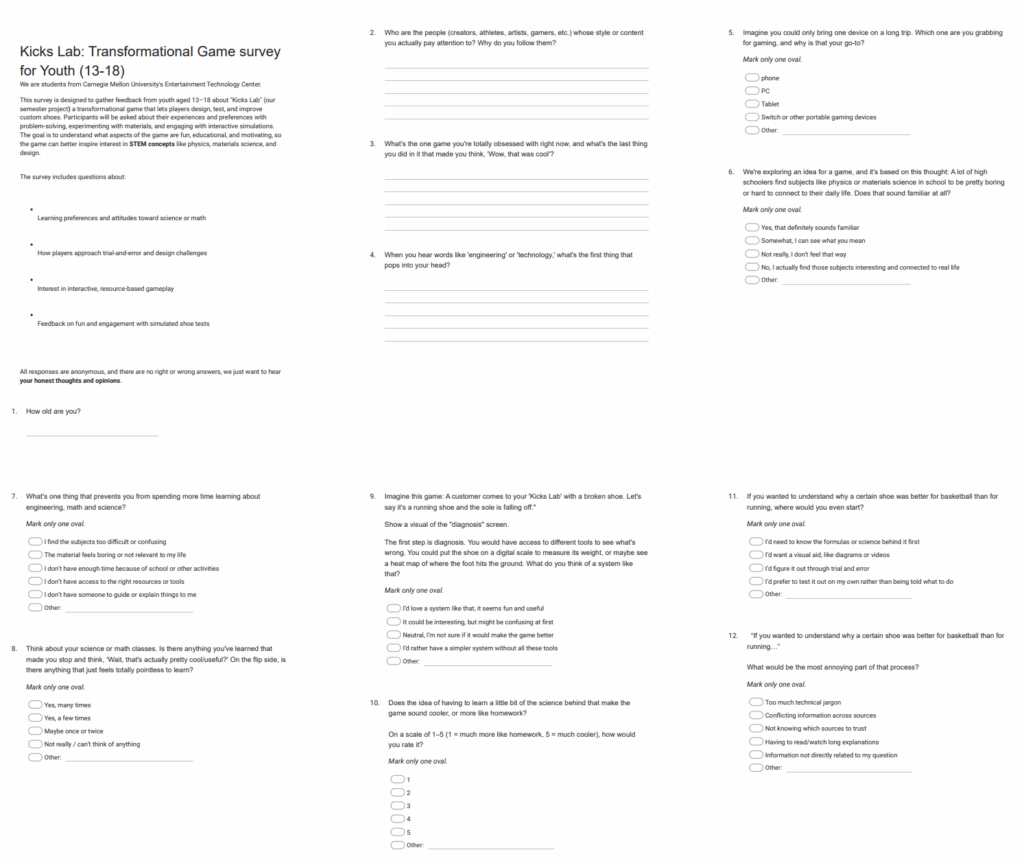

Outreach & Youth Engagement

Outreach continued to expand this week. Sam followed up with Ben, who connected us with several youth-oriented groups in Pittsburgh, including:

- Assemble

- LIFE Male STEAM Academy

- City High

We sent an introduction email and requested support for educator interviews and student playtests. Scheduling with both teachers and students (ages 13–18) is now underway—a major step toward grounding our design in real player feedback.

Creative & Documentation

On the creative side, Skye and Jiwon finalized our logo, poster, and half-sheet design, marking a big milestone for visual identity. We also:

- Continued brainstorming in FigJam on the gameplay journey.

- Pushed forward website development (despite a few publishing snags).

- Kept building strong documentation to track updates and align the team.

Looking Ahead to Week 5

Next week, our focus is on action:

Next Tuesday: Meeting with Onur Gun (New Balance) for the designer/engineer panel call.

Next Monday: Client meeting with Ansys to present a wireframe and confirm scope.

Next Tuesday: Test our prototype based on the gameplay loop at Playtest Night.

Finalize the poster and logo rollout.

Confirm youth sessions and launch the teen survey.