Building Flow and Finding Footing

Week 8 marked our first official sprint—and the first time our shoe design game was tested by real players. With a hard deadline set for the playtest at Life Steam Male Academy on Monday, October 27, the week quickly became a blur of designing, refining, and rethinking how to turn material properties and shoe science into an engaging, intuitive experience for students.

Setting the Stage

Coming out of early prototypes, our main goal was to connect gameplay with learning. We wanted players to not only enjoy building shoes but also understand how materials, structure, and design choices relate to performance in real life. The week began with refining our Minimum Viable Product (MVP): one complete level that would demonstrate the core gameplay loop—from customer request, to prototype, to testing, and finally, feedback.

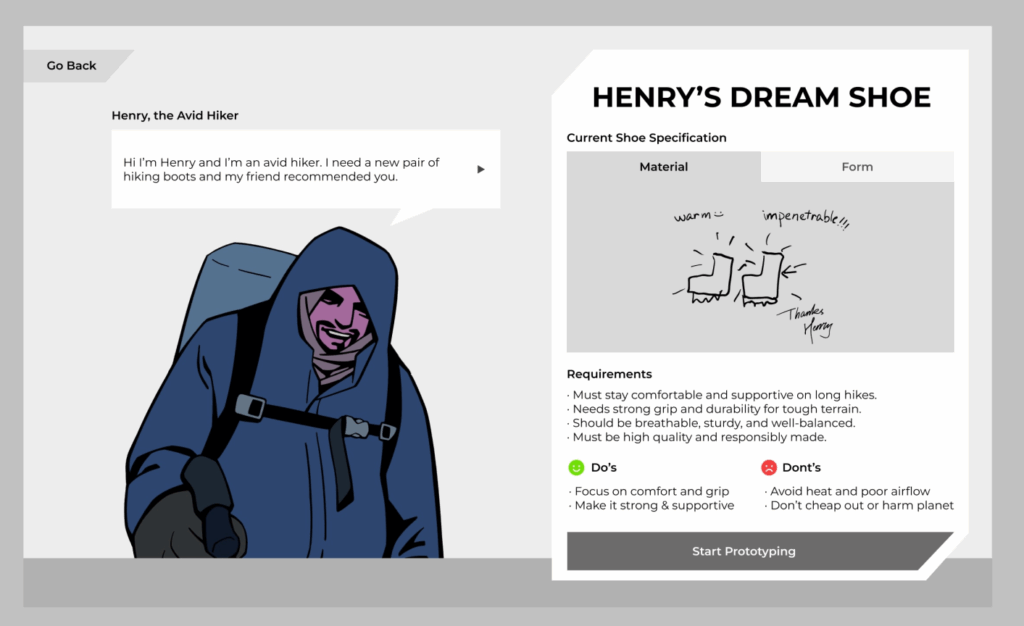

Libby and Samantha focused on getting that loop playable by Tuesday night. They started with new materials—lycra, nylon, and rubber—to replace placeholder options and build more accurate examples. Players would receive a “customer profile,” such as a nurse, firefighter, or construction worker, each asking for a shoe suited to their environment. We also added a fun cross-training challenge: balancing needs between two sports, inspired by Bo Jackson, who famously played both football and baseball. These character archetypes helped us ground our system in the real world and connect with players’ lived experiences.

Prototyping the Play

By midweek, the project split naturally into focus areas.

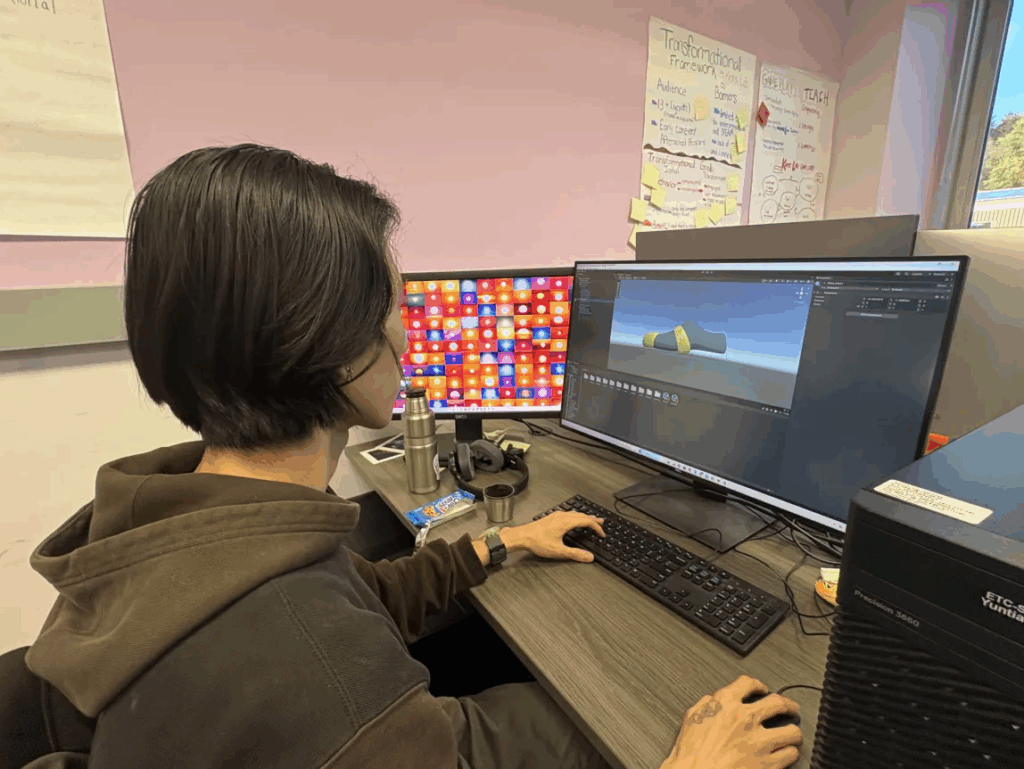

Steven built out the core game logic in Unity, making sure each shoe part’s properties could be calculated and tested. Jiwon worked in Figma to create a flow-through tap prototype—something we could quickly iterate on visually. Skye began developing art assets and test animations that would make the lab feel alive: buttons lighting up, machines bubbling, and background illustrations hinting at each customer’s world.

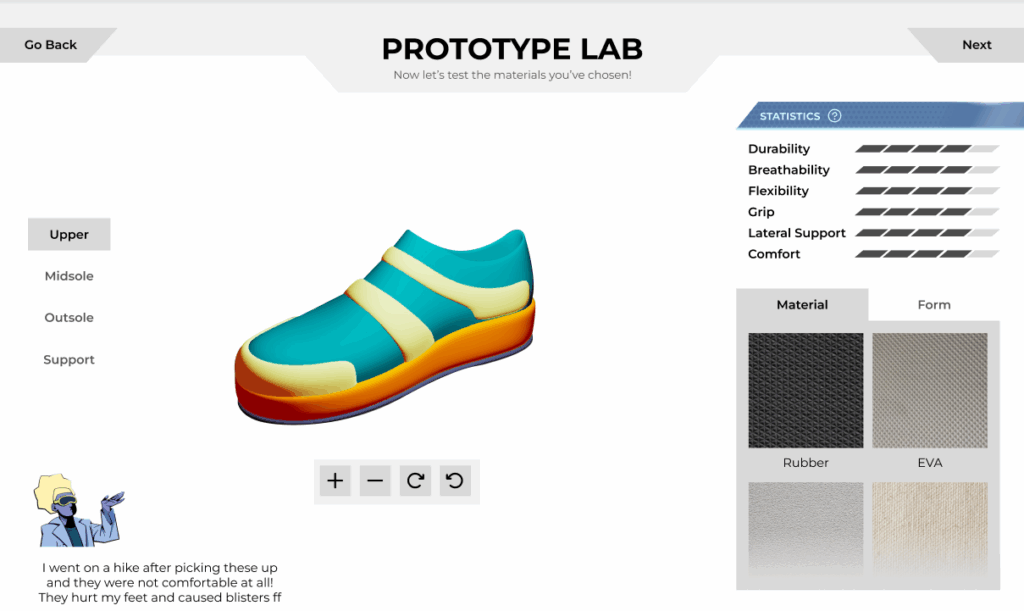

Together, the team mapped the formula that underpins the entire experience:

Material Property × Part Weight = Shoe Property.

Each category—comfort, durability, grip, lateral support, breathability, weight, price, and sustainability—would contribute differently to the final shoe’s performance. We wanted players to feel like their design decisions had measurable consequences.

Testing the Test

Our consultant meeting with Dave on October 24 helped us think deeply about flow—the balance between challenge and support that keeps players engaged. We talked about transformational goals, usability, and what it means for players to “understand” testing, rather than just watch results appear. Dave pushed us to consider how players might infer hidden thresholds, like guessing what level of grip or durability their customer really needs, and then adjusting based on feedback.

From that conversation, a new idea emerged: before heading into the lab, players could interview their customer, making educated guesses about priorities. After testing their design, they’d see which assumptions held true. It turned testing into a cycle of discovery rather than a checklist.

We also discussed visual design tweaks: linking stats directly to shoe parts through highlighting or animation, simplifying UI elements, and making the testing phase more tactile. Instead of passively receiving results, players might push buttons to “run” the test or watch a machine come to life. This sense of interaction, we realized, could make the learning experience feel more authentic.

Playtest Day: Life Steam Male Academy

By Friday, everything came down to our upcoming playtest scheduled for Monday. We structured the session carefully—almost like an experiment. Four groups of students would rotate through different testing sequences, each combining interviews, gameplay, and post-session reflections.

Group A began with a naive playtest—jumping straight in with little explanation. Other groups experienced added layers of scaffolding: pre-interviews, user relatability questions, or extended post-play conversations. Across 50 minutes, we gathered data on how support, challenge, and curiosity shaped engagement.

Our design lens was “flow”: starting with something challenging but offering support through hinting and scaffolding. We watched for confusion, for moments of discovery, and for how students interpreted the link between stats, materials, and the shoes they were building.

Insights and Next Steps

The playtest showed us that players were curious, but sometimes unsure how their material choices translated into test outcomes. The experience worked best when players were given relatable contexts—like work boots or sports shoes—and invited to draw on what they already knew about footwear.

As a team, we realized that our game wasn’t just about picking materials; it was about thinking like a designer. Players needed to interpret needs, experiment with trade-offs, and learn from failure states that actually made sense.

Our next steps are clear: make the testing lab more active, clarify how results connect to design decisions, and strengthen the relationship between story and science. Week 8 taught us that creating an engaging learning experience isn’t just about coding features—it’s about understanding how players think, what motivates them, and how small design choices can make big educational impacts.